NEWS

All categories

EDUCATION

EDUCATION

Here you can find some information about calipers, digital calipers, vernier

calipers, micrometers, indicators, depth gauges,and digital height gauges.

What's a caliper?

A caliper is a device used in the metalworking field of mechanical engineering,

to measure the distance between two symmetrically opposing sides.

A caliper can be as simple as a compass with inward or outward facing points.

After the measurement is taken the distance can be read by applying the

caliper on a ruler or between the jaws of a vernier caliper.

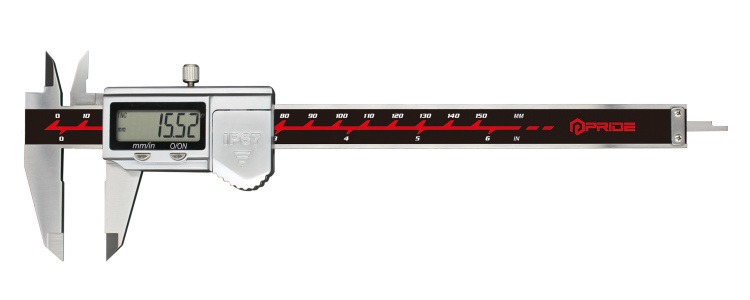

Digital Calipers -- Electronic Calipers

Digital Calipers also called Electronic Calipers. The striking advantages of

the digital calipers is that it is easy for us to read and gearless precision, with

both English and Metric Measurements. Nowadays, with the rapid growth of

high technology, some models of Digital Calipers come with SPC output.

Why choose SPC capable Digital Calipers?

The reason is that SPC (Statistical Process Control), allows for quick and easy

data collection when utilized with SPC software.It is vital that the user should

check digital calipers frequently for accuracy.

They are more susceptible to damage than other tools. Both the inside jaws

and the outside jaws need to be calibrated, as well as the depth rod and the step

measurement. To check for wear in the jaws, do this: clean them and close them.

Then hold them up to the light and if they're worn you'll see light shining through

the gaps. You can continue to use the calipers if you measure with the unworn

surfaces. For total reliability, however, you'll have to send the calipers for servicing.

The surfaces can be ground flat again.

To calibrate the inside jaws you may use a set of ring gages, but you may

also set a calibrated .0001" micrometer to 1"(and higher, if possible) and

then use the inside jaws to measure this distance. Since the micrometer

has a discrimination ten times that of the calipers, you'll get an accurate reading.

For the outside jaws it's a simple matter of inserting a series of gage blocks

between them and recording the caliper readings.They must not deviate by

more than one graduation (.001") over the first 4" of range. From 4" to 8"

the error may be .0015" (one and one-half graduation). From 8" to 12" the error

can be .002". Accuracy may vary among different models and the manufacturer's

specs should be consulted for this information. Take readings at 1inch intervals.

Three gage blocks (see below) of 1", 2" and 3" sizes will be all you need.

What is a vernier caliper?

A vernier caliper (or vernier) is a common tool used in laboratories and industries

to accurately determine the fraction part of the least count division. The vernier is

a convenient tool to use when measuring the length of an object, the outer diamete

(OD) of a round or cylindrical object, the inner diameter (ID) of a pipe, and the depth of a hole.

The vernier caliper is used in length measurements to gain an additional digit

of accuracy compared to a simple ruler.

A vernier caliper is a measuring tool. It can make inside, outside, or depth

measurements .It is marked in both USCS and metric divisions called a vernier

scale. A vernier scale consists of a stationary scale and a movable scale, in this

case from the vernier scale.

A vernier scale has a movable scale that is parallel to fixed scale .These precision

measuring instruments are capable of measuring outside and inside diameters

and most will even measure depth. Vernier calipers are available in both imperial

and metric scales. The main scale of the caliper is divided into inches, most

measure up to 6 inches. Each is divided into 10 parts, each equal to 0.001 inch.

The area between the 0.00i marks is divided into four. Each of these divisions

is equal to 0.025 inches.

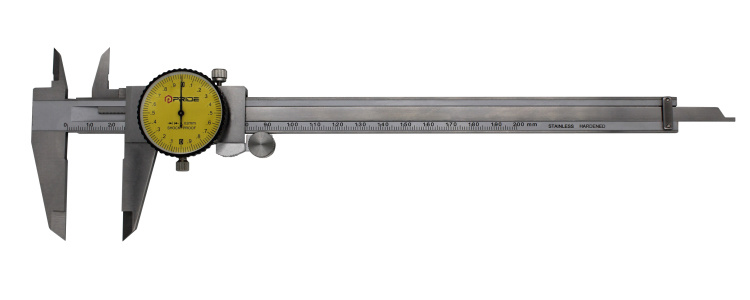

What is a dial caliper?

An easier to use version of the vernier caliper is the dial caliper,USCS calipers

commonly measure dimensions from 0 to 6 inches. Metric dial calipersusually

measure from 0 to 150 mm in increments of 0.02 mm. the dial caliper features

a depth scale , bar scale, dial indicator , inside measurement jaws, and outside

measurement jaws.

The main scale of a USCS dial caliper is divided into one-tenth(0.1) inch

graduations. The dial indicator is d divided into one-thousandth(0.001) inch

graduations. Therefore , one revolution of the dial indicator needle equals

one-tenth inch on the bar scale.

A metric dial caliper is similar in appearance but the bar scale is divided

into 2-mm increments. Additionally , on a metric dial caliper, one revolution of

the dial indicator needle equals 2mm.

Both USCS and metric dial calipers use a thumboperated roll knob for fine

adjustment. When you use a dial caliper always move the measuring jaws

backward and forward to center the jaws on the object being measured .

Make sure the caliper jaws lay flat on or around the object . If the jaws are

titled in any way, you will not obtain an accurate measurement.

What is micrometer?

A micrometer is either (a) a device used to measure very small distances,

usually accurate to 1/1,000 of a millimeter, or (b) a metric measure that is

exactly 1/1,000 of a millimeter, or 1/1,000,000 of a meter. It is a device widely

used in mechanical engineering for precisely measuring thickness of blocks,

outer and inner diameters of shafts and depths of slots. Appearing frequently

in metrology, the study of measurement, micrometers have several advantages

over other types of measuring instruments like the Vernier caliper - they are

easy to use and their readouts are consistent.

The major components and markings of a micrometer include the frame, anvil,

spindle , locknut , sleeve , sleeve numbers ,sleeve long line , thimble marks ,

thimble , and ratchet. Micrometers are calibrated in either inch or metric

graduations and are available in a range of sizes.

What is a depth gauge?

The depth gauge is another popular variation of a linear measuring instrument

with a veinier reading and specialized anvils.

The design gauge is used to measure the depth of holes and steps.

What is a digital height gauge ?

Digital height gauge is also called electronic height gauge.It is used to mark

out lines when accuracy is particularly important.

Digital height gauge has a large steel base for stability and a hardened steel

column engraved with inch and mm units.

The moving slide is engraved with vernier calibrations enabling settings to

an accuracy of 0.02mm and 0.001''.

Attach to the moving slide is a wedge-shaped steel scribe that has a pointed

tungsten carbide tip. The height of the scribe's point can be finely adjusted with a thumbscrew.

Prev

Next