PRODUCTS

- Product description

- Specifications

-

Computer Control High Precision Surface Tester

1.Application:

RUG-500 Computer Control High Precision Surface Tester isa probe style profile measuring instrument. It is applicable to

measure surface of various types of parts,such as planar, incline, cylinder,circular and spherical parts, grooves and bores.

It is also applicable for measuring roughness of roll path, eitherouter or inner of bearing.

It can realize the shape of the surface roughness, measurementof parameters such as the outline of peaks and valleys, but also

for measuring the work piece TP steps.

The Instrument has convenient usage, high accuracy,repeatability and stability etc features.

The instrument is equipped with computers and dedicatedmeasurement software,the use of advanced noise-free

mechanical positioning device can be selected to be measured

at different positions, and set various measuring the length of the automatic measurement, assessment segment sampled data up

to 4000 points.

All measured data and curves can be widely used in the autoancillary industry, machining, precision cutting tools, molds,

scientific research units, universities and other major industries

in the screen display or printout, so widely used in the auto

ancillary industry, machining, precision cutting tools, molds,

research institutes, universities and other major industries.

2.Standard:

It is compliance with International Standard ISO5436, ISO11562. -

3.Technical Parameters:

Model No.

RUG-500

Evaluation

Parameters

Ra,,Rz,Rt,RS,RSm,Rp,

Rv,Rmax,Rq,D,Pt.

Lr,Ln,RSk,RΔq,Δa,λq,λa,

R3t,Rt1,Rt2,Rt3,RT4,Rt5 etc.,

Rmr(Tp)Curve.

Roughness

Range

Ra 0.01~50 µm

Sampling

Length

L: 0.08 ,0.25,

0.8, 2.5 mm

Evaluation

Length

Ln: 1L, 2L, 3L, 4L,

5L, Can Selectable

Sampling

Points

4000 Points

Resolution

0.001 µm

Indication

Error

± 5 %

Repetition

Error

± 3 %

Max. Specimen

Height

300 mm

Application

Planar,Incline,Cylinder,

Circular and Spherical Parts,

Grooves and Bores.

Probe

Standard Type,

Height < 8 mm.

Special Probe For Small Bore,

Radium: 2 um,

Pressure: 4 mN

Traverse

Speed

2 mm/s

Traverse

U/D Mode

Automatic

Scanning

Speed

0.5 mm/sec

Linear

Range

Vertical 640 um

Thickness

and Pt Range

100 um

Resolution

0.1 um

Longitudinal

Range

60 mm

Profile

Graph

Macro Profile,

Filter Profile

X, Y

Magnification

Automatic Mode

Filter

ISO 2CR Filters

Measurable

Range Of Bore

≥ Ø5 mm

X-Y Stage

Rotation ±10°;

Declination ±10°;

X-Y Adjustment 15 mm

For Measurement

Of Bearing

Max. Outer Dia.

Of Inner Ring 280mm

Min. Inner Dia.

Of Outer Ring 12mm;

Thickness: ≤160 mm

Printing Paper

A4

Operation

System

WinXP

Granite

Base

700*400*100 mm

Gross

Weight

100 KG

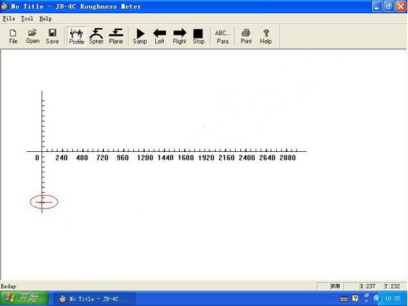

4.Software Interface:

5.The Packing